Keith Christensen

Keith Christensen was raised in the town of Norwalk, California, the same town that Sam Barris of Barris Brothers customs and Hildebrandt Manufacturing owner Dennis Hildebrandt lived in.[1]

Contents

- 1 Driveshaft Tips

- 2 Ball Road Street Races

- 3 First Car

- 4 Hildebrandt

- 5 The Norwalk Coachmen Car Club

- 6 The Norwalk Motorcade

- 7 Tijuana Upholstery

- 8 Hanging out with Von Dutch

- 9 "Keith, Pull it Inside the Shop, I Have a Great Idea!"

- 10 Car Lowering Adventures

- 11 Keith Joins Kustoms of America

- 12 Keith is First Introduced to Larry Watson

- 13 Gene's Mufflers

- 14 Larry Watson moves in next door

- 15 Bellflower Chrome Tips

- 16 Lifted Sedan Delivery

- 17 The Action Mufflers Sedan Delivery

- 18 The Phone Company Truck

- 19 Racing Days - The Little Hudson That Could

- 20 Tom Kelly

- 21 Lake Havasu City

- 22 Keith Christensen's Cars

- 23 References

Driveshaft Tips

Keith's father was a Doctor's veterinarian, and he did work in Norwalk and the adjoining town of Artesia. Keith had an older brother who hung around with a group of Dutch brothers, the Goedharts. In 2016, Keith told Kustomrama that his dad had built a good-sized workshop at their home; "Dad was a lover of blacksmithing, so he had torches, lathes, tools and more. Myself and two of the Dutch brothers would go to every old wrecking yard, as in 1950 there were many here in California. We would buy the inside of a 1936 Ford driveshaft, as the shaft was enclosed in a closed driveshaft housing, called a closed driveline. The actual driveshaft was tapered on either end and had a u joint attached on each end. We would cut the u joints off and cut the driveshaft right in the middle, giving us two equal pieces that both tapered on one end, so the shafts started at 3 1/2 and after 20 inches tapered down to the hollow end that where the u joints had been removed, which had a 2" opening. The 3 1/2 end, we would go around it heating in with a torch and tapping it down to a nice bevel, leaving a 2 1/2 opening. That gave us a small end, and a large beveled end helped to make the famous motorboat sound that was heard on all good custom cars. We, of course, had them chromed, and they had to be welded on to the car's exhaust outlet, just under the bumper. They were 14 gauge so a low rider could scrape up a driveway without hurting them." According to Keith, this is where the famous name "Driveshaft Tips" came from; "Myself and two Dutch kids invented the Driveshaft Tips and couldn't find enough 1936 Ford driveshafts to make enough for the waiting line of guys that wanted them. Keep in mind I was 13 years old at the time. My Dad's workshop is where we cut and beveled them. Later on, when I opened Genes Muffler, I realized there were few, if any 1936 Ford driveshafts. The supply had dried up, so I started making them out of 16 gauge tubing and putting a taper on the one end with a swedger that I had dies made for. Perfect as one end had a short taper and the other a real nice bevel."[1]

Ball Road Street Races

Before the Coachmen club was formed, Keith would go out to a street called Ball Road, "in the rural dairy lands." Ball Road was wide, straight, and dead-ended into a riverbed that separated Artesia from Anaheim on the other side of the riverbed. "In fact, Ball Road on the other side ran through the property that later was the south side of Disneyland before it was built." Keith recalled that they would meet there at one end, at night, and set up a race court. "There were no side streets to create a problem. I was too young to even have a driver's license at the time, my older brother Bill was an avid car builder and built many hot rods while still in high school. He was a master at building flathead engines and had a hopped-up, customized 1940 Ford. He and I would drive out there and race all the big boys with their V-8 Oldsmobiles and even some Cadillac coupes belonging to the Dutch and Portuguese kids. I remember well those, to me, giant old cars with the first of the overhead, high horsepower engines." Two cars were lined up, and when someone at the other end, by the dead-end, would blink their lights, the cars would take off. "Then turn around and head towards us at the original start line. It was really intense and exciting. So well do I remember the two cars coming back towards us, and one being my older brother, would be roaring our way, almost a 1/2 mile off. I could squat down and see the headlights and would get the greatest thrill to see my brother's headlights out from. Easy to tell as a 1940 Ford had headlights in the fenders close together, and I could see when he was winning against those big cars that were super wide. A grand memory for me." They had about 20 minutes of no-traffic racing, and they knew that the law couldn't jump in except by the west end of the race area. "It took them that long after finding out about our activities to get there. We would scramble out that end of Ball Road just in time. Heading towards the tall alfalfa fields on either side. Many a time, my brother and I would get home and have to pull all the alfalfa clumps out from under his car before cleaning the car." According to Keith, this was truly what was called an age of innocence, as there were very few other activities to take part in. "This was a basis and motivator for us setting up the large Motorcade car show and lent to its success, with the wonderful cooperation of Excelsior High School and the Junior Chamber of Commerce being our backers. A mixture of many small cities, Norwalk, Artesia, Bellflower, Long Beach and many other cities."[1]

First Car

Previous to the days of high school and dating, Keith owned many cars, but his first real car to enter the social world was a 1950 Oldsmobile Business Coupe; "It was when Chevrolet was just six cylinders, Fords were flatheads or low horsepower OHV engines. The Olds was truly the fastest of the cars in my day as a stock-equipped car. Pure stock it was sure fast, and a lot of tickets later, I learned how to control it. Kettering designed the engines, and they were used in Cadillacs and Oldsmobiles. "[1]

Hildebrandt

When Keith was in high school, he was working part-time at an automotive adaptor manufacturing facility just north of Moon Equipment; "I was working at Hildebrandt mfg. A small personal activity I crammed into my busy high school world. They made engine adaptor plates for installing the big Chrysler Hemi's into Chevy, Ford, and all else. The adapter plates were machined aluminum plates with holes drilled to match up to many different transmissions. A truly fascinating business for me. Dennis Hildebrandt belonged to the Qualifiers car club, a group of older hot rodders that built and drove some very exotic cars for their time."[1]

The Norwalk Coachmen Car Club

Keith was the first President and a founding member of the Norwalk Coachmen car club. In 2016, Keith told Kustomrama that the club started in the living room of his folks' home in Norwalk in late 1952; "Norwalk is southeast of Los Angeles, approximately 22 miles. It was an area of farms and dairies, which of course, have faded due to rural buildup. This is why you will see many names of the two dominant nationalities, Dutch and Portuguese, as owners of many hot rods and low riders."[1]

"We flourished and expanded the club to other communities and had a total membership of 135 members in 1956. At that time, I stepped down after being President for all of those years. I went off to college, and the car club finally disbanded in 1958."[1]

The Norwalk Motorcade

The Norwalk Motorcade was an outdoor hot rod and custom show sponsored by the Norwalk Coachmen car club. According to Keith, it was inspired by the club, and the show became known as the Coachman Show. It was held with help from the Norwalk Jr Chamber of Commerce. The first show was held in 1954 at Excelsior High School in Norwalk, California. Keith was the Director of the show, and it became a huge success; "We promoted it and developed a lot of contacts. We held it on the grounds of the high school we all attended, Excelsior High School. The show expanded to encompass all of the grounds on all sides and brought a huge crowd as we drew in entries for many communities in the outlying areas. This was the babyhood of car shows. No one had 'yet started doing this as the customizing era had just started, and we were ground floor. At its peak, we had displays from all of the local car dealers, the Army National Guard, the Motorcycle shops, and many others, and about 4 acres of showgrounds. I was able to get our club member, who was a photographer, to film much of the shows. We even got him a ride in an airplane to fly over and film from the air." Working for Dennis Hildebrandt, Keith had rubbed elbows with the members of the Qualifiers car club, so he used some of their cars to enhance the Motorcade show; "They helped add that quality touch to the shows."[1]

Tijuana Upholstery

Before meeting Eddie Martinez, Keith took a car to Tijuana to have it upholstered. "After searching the dingy back streets of the town, I found the one shop that was recommended by a few guys. There were a few cars and their owners waiting to get done. After doing the typical bartering and arguing about the price, I accepted, and they pulled my car into the work area. I was 17 at the time, so I wasn't wise to the ways of businesses south of the border." They immediately tore the seats out of Keith's car and took off all the old upholstery. "Then the waiting started. I stood along a wall with the other customers and, after talking to them, realized what a position I was in along with them. Once our cars were torn apart, we were trapped. The wait was on. I remember so well, the sun going down and there sat my car, seats all over the ground." About 9 o'clock that night, they finished, and Keith drove the dark dirt roads out of Tijuana and into San Diego and on home `90 miles. "Boy were my folks worried ..."[1]

Hanging out with Von Dutch

In his youth, Keith used to hang out at Von Dutch's shop, "which was a garage attached to a motorcycle shop in Compton," he told Sondre Kvipt. "I started, out at first, with idle curiosity and then admiration of the works of Von Dutch. I would go over after class at high school and just "hang out."" Keith recalled that there always was something to look at on the walls or a job in progress by him. "What a world of real art. As I remember, he had a picture on the wall of a giant battleship, with a handwritten caption on it by him, saying, "I DON'T STRIPE BOATS."" Back then, Von Dutch's talent and interest were mainly motorcycles, not cars. "He had small inventions sitting around that he was in progress with, and they were genius in their design. I remember a motorized set of roller skates that were powered by model airplane motors, and the rider had a backpack with a small battery and a fuel tank hooked to the skates. He used one axle as the drive axle, using the shaft of the airplane engine hooked to the wheel. He was mad that he couldn't solve the puzzle of two things, ONE, to be able to not go in circles due to only one drive axle, and SECOND, how to stop as he had to set the motor speed by hand before starting the engine."[1]

"Keith, Pull it Inside the Shop, I Have a Great Idea!"

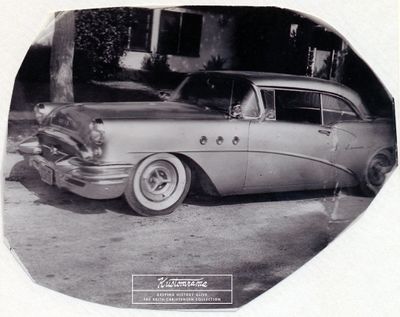

In late 1954 Keith Christensen bought his first new car, "a 1955 Buick! Polar white and beautiful dark green leather inside. I drove a 1950 Olds 88" before that. It was SUPER fast, but not enough design with all of the new cars out on the market." When Keith pulled into Dutch's shop, he saw it and said,"Keith, pull it inside the shop, I have a great idea!" "Not knowing what he had in mind and too scared to ask, I pulled it in. "He said those portholes on the side are super cool!" They were the first of the perfectly round portholes. I stood back, and he started masking and taping down both sides. There sat my beautiful, NEW Buick, all stock, not customized yet, and at his mercy! Boy, I was scared! He got a small airbrush and proceeded to paint bright "RED" flames coming out of the portholes and running down the sides to the front doors. He was super happy! He said, "They look great. They just fit" I stood there grinning and agreeing with him. I was stunned when he said, "Hey Keith, it's on the house, I've been wanting to do one ever since I saw them." Well, I drove home and into the reality of, "what will my folks say?" I was only 17, and they had cosigned on the car. I hid it around the corner in a friend's driveway. I told my folks, a fib, that it was being tuned. I finally brought it home, and they were much better about it than I thought. They were so interested in my endeavors that it was accepted. One solace was I had started the Coachmen car club at my house a year earlier, and when the members saw it, they couldn't say enough good about it!! That was in 1954, and it was such a new world of customizing cars that this just re-enforced the desire to make an outstanding car out of whatever you drove, and that was just the beginning of my building that Buick into a real custom car."[1]

Car Lowering Adventures

Late in 1955, early 1956, Keith was a junior at Excelsior High School, and his younger brother Wayne was a freshman. "We both had paper routes, and I worked as a box boy at the local supermarket. We saved our pennies and nickels, and both came up with a down payment on a new car. I picked a 1955 Buick, and later in the year, my younger brother bought a 1956 Oldsmobile the minute the new model came out. Real snazzy. Both were 2 door hardtops, and we couldn't wait to start customizing them. The lowering craze had just started, and we jumped on the idea of making the cars low! We opted to start on Wayne's Oldsmobile first. We were lucky that our Dad, in his kid days, lived on a ranch in Colorado that had a huge blacksmith shop, so our dad put in all the rudimentary tools of working with metal - Torches, metal saws, arc welders and such. We were sitting in an opportune position of being able to customize cars. That's where our first step came into being, and that was to lower a car!"[1]

Keith and Wayne got out in the side driveway next to their house. Keith got under his brother's car and heated the coil springs, "one wrap at a time. It sure wasn't precision, as I would, after heating a coil or two, get out from under the car, and we would both look, and one side or the other was lower. So back under the car and heat another coil and onward with the mission to make that new car low and sleek. Wow - Fun! Well, the axle running crossways of the rear moves up and down with the bumps in the road and, when reaching the bottom, would hit rubber snubbers on each side of the frame. Well, we stopped and pulled the Olds out and took a look and decided it looked good, so we drove it down the street, and wow, each bump the axle sitting on the snubbers didn't have any play - Every bump in the road was a super bounce inside the car. Well, I knew how to cure that, I thought, or so I thought. We jacked the car up and cut the snubbers in 1/2, now we had a little play on the bumps in the street." Out onto the street they went, and the first bump was a sound beyond description. "Metal against metal, the loudest teeth-rattling sound we had ever heard. Especially inside the car. The U joints and driveshaft, spinning underneath, were hitting the floorboards as they spun! Of course, U-joints aren't round, and the sound of them spinning and banging was huge! We nursed the Olds back into the driveway and parked it. Really perplexed. My brother suggested we make clearance for the driveshaft because we didn't want to install new springs' and raise the car up, as it sure looked snazzy to us."[1]

"Our poor folks weren't aware of our project, or a halt would have been in line. We opened up the inside of the new Olds and removed the rear seat and floormats and all the padding in that area. We stripped it from the back of the front seats to the trunk. Now we were down to the metal, so I got my Dad's acetylene torch set and got inside, with my brother Wayne standing outside with a fire extinguisher in hand, I started cutting the floorboards above the driveshaft area. Cutting a long slit the full length from the front seat to the trunk. WOW," fire and smoke beyond description! I kept a spray bottle of water at hand inside just in case, as all that new car material was close at hand, like door panels, rear of front seats, package tray, and even headliner. We were in luck, nothing caught fire. We spread that slot apart, and there below it was the driveshaft.

Now that the slot was open, we had to make it higher for the driveshaft not to rub. So we found a ready-made item, a rooftop drain trough. Cut it to length, and it fits right over the opening we made. Now came the tough part, welding that upside-down drain through to the floor, which would end up under the back seat cushion. Well, with a lot of cutting, fitting, and welding, we got it hooked to the floor and used undercoating to seal it. Then we realized the center of the rear axle (the third member) was sticking up farther than any other item of the drive train, so here we went again, two young teenagers doing more cutting inside the trunk. We opened a square hole over the top of the center of the axle and mounted a square metal box, and welded it in. This was the tough part as there is only room for about 1/2 a person in the trunk, and us standing on our heads, we really fought this part of our big, painful project of lowering a car."[1]

Then it was out onto the street again. Another road test. "We were in our glory and lower than any car in town. Excepting, there was an even louder awakening. We realized the axle was hitting the frame on each side. Without the snubbers, it was metal to metal, and that was the loudest clank ever heard. It reminded a person of a jackhammer. Back to the driveway. We jacked it up. Now mind you, it was a new Oldsmobile, and we felt like we were modifying Detroit's total design all to look cool and low! Well, on either side, I cut an upside-down horseshoe section out of the frame where the axle was hitting A slot shaped like a channel iron - 1/2 of a rectangle. We made two angle iron pieces, and I welded them into the frame in the spot I had cut out, just above the axle. Now that Olds axle could travel up into this wide rectangle notch, I made in the frame. Wow, again we had the lowest of low cars in town. Mind a person, this was long before hydraulics and airbags. We didn't road-test it. We just bounced it right there. The rear bumper hit the cement and so up in the air again and install back in the rubber snubbers, but this time up in the notch in the frame, and the axle just sat right down on them. You could get a pack of cigarettes upright under the edge of the bumper and not an inch more. That was really low! I heated the coils in the front, which was an easy task and got the car level front and rear. What a beauty, we thought even though it was impractical, it sure looked neat. Another day or so of putting the car back together inside, and we had a lowered 1956 Oldsmobile. Our pride and joy!!" Keith and Wayne put off doing Keith's 1955 Buick for a while as they were all projected out. "Later in my youth, after buying Gene's Muffler, I did a few more c-framing and lowering of cars, but it was way too labor intense and not profitable. So the next step was to start installing hydraulics, and that was very profitable."[1]

Keith Joins Kustoms of America

"In January of 1955, after a few visits to Barris' shop on Atlantic Blvd., I was let into the back room of their facility. There was Sam Barris working on an old Mercury. He was cutting the top off. Now, in later thought, I realize he was chopping the roof of the car. In the middle of meandering, I was stopped short by George. He said something like, "Hey kid, what are you doing in here?" I told him that I had been there the previous week and that he had lowered my 1955 Buick, and he replied, "Oh yeah, I remember you." He said, "Come on into my office. I want to show you something." After we entered, he went over to his desk and pulled out a card, and said, "Do you want to join my elite club, 'Kustoms of America'?" I said, "Sure." So, he sat down and typed my name onto the card. He then explained that I would get certain benefits at no charge. I don't remember what they were, something about a newsletter and notices about upcoming shows."[1]

Keith is First Introduced to Larry Watson

Keith met Larry Watson in 1955 when he visited a Coachmen car club meeting. "He was introduced that evening to the club members. When we took our break, the gang went outside to look at the pinstriping work he had done on his own car - a little 1950 Chevrolet. It was Chocolate brown on a tan car and the quality of work was outstanding. This was previous to him starting up his painting vocation."[1]

Gene's Mufflers

In 1958 Keith had just gotten married. He was in College and worked at a Supermarket; "I took my bosses 1956 Ford truck and my 1955 Ford truck to a tiny shop where my younger brother started working. Aman in the Jr Chamber, who sponsored the Coachmen car club, had a muffler shop in Norwalk. A short distance by the way from where Sam Barris lived. He gave my younger brother a job sweeping and cleaning his muffler shop, called Sport Muffler. My brother learned the muffler trade and in my getting acquainted with Gene, I got him a job there. It was called Gene's Muffler. Located on the border of Paramount and Bellflower, the shop was an old real estate office and a two-car garage that Gene had put a pit with a couple of racks in between. Coming into that little shop, I noticed Gene was doing great and I told him if he ever wanted to sell the shop let me know. He was driving a fairly new 1956 Ford pickup, had a wild ski boat and a new car for his wife. Not bad for a young man!"

Later on, Gene got in trouble with the sales tax department and needed money; "I hocked everything and paid $3,500.00 for the shop. The name had a good reputation so I just kept it. Later I bought the land next door and built a very large muffler shop that could do 6 cars at a time. In the front building I put a tire and wheel company and a small manufacturing building in between. It did great so I put shops in Downey and Hollydale, two cities nearby. We did all of the lowering and lifting of cars and installed dual exhaust on thousands of cars over that period.''[1]

Larry Watson moves in next door

In his youth, without a beard or styled hair, Larry Watson moved into a building directly across the shop area from Keith's original muffler and customizing shop. "There he took on his aura of beard and styled hair," Keith told Kustomrama. As Watson progressed, Keith remembers Watson first opening up a little shop next to Nance Chevrolet company on Bellflower Blvd in Bellflower. "He started painting cars,"Keith recalled. "He would wet down the floor of an old garage for the sake of dust, and painted inside. It wasn't long before the fire department came and close him down." Keith remembers Watson then moving over on to Park street in another small garage where he went through the same scenario. "From there he moved in next to my shop on Lakewood Blvd, in Paramount, across the street from the border of Bellflower. He had a group of back yarder's come in and install an old paint booth he had found and bought." Watson was finally legal, and Keith remembers him advancing from a few custom paint jobs to Candy paint and onto gorgeous pearls.[1]

As Larry matured, he became the great painter that everyone would recognize. "In the early 1960s he started innovating painting. From flames, to blending of colors, to two tones of the very expensive Murano pearl, which at that time was made up of abalone seashells blended into the paint. It was astonishing what he developed and did," Keith remembered. "Lacing the sides of a car was marvelous, as seen on Doug Carney's 1963 Pontiac. I helped Larry with a couple of lacing jobs. We would set up saw horses on either side of the car and have to position them perfectly - just inches away from the side of the car - tedious and critical. Then we would take an expensive lace table cloth and stretch it between the sawhorses - even more critical a distance. This is all after the car had just been painted some wild Candy or Pearl." The finesse of the next step was the crucial step, Keith recalled; "Larry had only one pass along the side of the car to fog through the lace. He would take a beautiful paint color and turn the pressure of the paint gun up and walk the full length of the car in one long smooth, balanced sweep. A real test of talent as Larry would not have a second chance, as the paint would fog through the lace tablecloth and onto the side of the car and had to land perfectly and equally - No second chance. If it was not perfect, the whole side of the car had to have the lacing fog taken off." According to Keith, "Larry's intricate preparation and his talent came out in all this. The paint jobs were the talk of the town and won awards at a lot of car shows."[1]

Bellflower Chrome Tips

Keith started building Driveshaft Tips and Bed Rail Pipes. He developed a manufacturing division, and after seeing how llifted cars were dragging up driveways, Keith got the idea to put a 90 degree elbow pipe on the front of his driveshaft tips; "I chromed the whole thing, that let us put them on the outside of the fenders, just behind the tires. Since I was next to the town of Bellflower, where I lived, I called them Bellflower Chrome Tips! The name stuck with them to this day," Keith told Kustomrama in 2016.

Lifted Sedan Delivery

In 1961 Keith had a 1959 Chevrolet Sedan Delivery that Doug Carney of Downey installed hydraulic lifts on; "I had a shop in Downey at the time. Doug got his parts from Douglas Aircraft Surplus. Later on he went to Palley's to buy parts for many of his lift jobs, as they were a giant aircraft surplus store in Los Angeles. When you bottomed the Chevrolet, a pack of cigarettes would not fit under the front. Larry Watson painted it a Murano Pearl Yellow with Goldleafing in the inserts on the sides. I had an aircraft company friend of mine that upholstered airplanes, do the interior in a chocolate. The sedan delivery was my daily driver and a bunch of fun to drive as you could lower while driving. That year Chevrolet had a real wide flat hood and it really looked wild on the highway."

The Action Mufflers Sedan Delivery

For his other shop, Action Mufflers, Keith built a 1949 Chevrolet Sedan Delivery. The '49 was Lavender and fixed up much the same was as the 1959 Chevrolet Sedan Delivery.

The Phone Company Truck

In 1962 Keith bought a 1956 Ford phone company truck with a box on the back that he built into a delivery truck. Larry Watson painted it Pearl Yellow and Keith installed wheels and a big motor.

Racing Days - The Little Hudson That Could

During the 1950s and 1960s, while owning Gene's Muffler in Paramount, California, Keith also ventured into advertising by sponsoring race cars. "Adhering to NHRA regulations, these cars were mainly stock or pure stock vehicles. Displaying a prominent Gene's Muffler logo on each door, we effectively reached our customer base on a weekly basis, significantly boosting our sales."[1]

"What better way to indulge my passion for race car driving and my business promotion? So, I wholeheartedly pursued this endeavor. In that era, I had numerous friends who were also customers. All of us united to form a social racing club." With the proximity of Lion's Drag strip in Long Beach, Keith and his buddies could engage in races every weekend.[1]

"Comparing those times to modern drag races, it's evident that our activities were quite amateur. The regulations were minimal, with the primary focus on ensuring the safety of all participants, thanks to NHRA's comprehensive rule-setting. Friday nights were indeed amateur nights, with cars lining up and racing one or two at a time. Worth noting is that this was the 1960s, so the fastest cars raced against the slowest ones, all in the pursuit of achieving speed and elapsed times. It was incredibly enjoyable and remarkably affordable. This marked an era of pure, unadulterated fun, and we had an abundance of it."[1]

According to Keith, this activity surpassed street racing in showcasing speed and the time taken to traverse the quarter-mile. "The results were displayed on a board above the track, and my buddies and I would cheer enthusiastically. In those days, the Corvette reigned supreme in the stock car racing domain. Of course, there were also Dodge and Plymouth models that individuals could custom-order from the factory with Hemi engines, and let me tell you, they were exceptionally fast."[1]

"Around 1962, a friend of mine approached me with a fantastic idea: Why not collaborate to build a super stock car? He was employed at a Teflon factory in Gardena, the vicinity of Ascot Circle Raceway, which was owned by J.C. Agajanian. This was perfect, as my friend's workplace was in close proximity. We tinkered with several cars, and my friend Glenn possessed a wealth of knowledge concerning the inner workings of engines and drivelines in various vehicles."[1]

"While Chevrolet was beginning to introduce racing enhancements into their factory car lineup, such as fuel injection, and Chrysler was experimenting with cross ram setups and dual 4-barrel carburetors, we decided to veer away from the intensely competitive realm of racing. After considering various options, we settled on a Hudson Jet, a compact economy model reminiscent of the renowned Hudson Hornets from the 1950s. This little car had a modest 6-cylinder engine with a displacement of 202 cubic inches. It wasn't the most visually striking vehicle, akin to a basic 1953 Ford, but it was selected due to NHRA rules stipulating that any dealer-offered performance equipment could be utilized."[1]

"Interestingly, Hudson had enjoyed considerable success in NASCAR racing with the Hornet, featuring an array of racing modifications. They dominated NASCAR for three years, triumphing over many new, more powerful V-8-powered cars. Glenn and I saw a unique opportunity to apply the same principle to our Hudson Jet. According to NHRA regulations, any factory-provided equipment was permissible in the stock class. Glenn informed me, "Keith, I have the time to scrounge up parts for our car." He acquired a dual carburetor manifold, a high-compression 6-cylinder head, and a rare cast iron exhaust manifold."[1]

"Our stage was set. Having recently constructed a more spacious building for Gene's Muffler, we had ample room to experiment and enhance our diminutive Jet. Countless hours were devoted to experimentation and weekend tests at Lions Drag Strip, and our efforts bore fruit. Our elapsed times decreased while our speeds increased week by week. Initially, we managed a speed of 68 miles per hour in 18 seconds, with even a 4-cylinder MG outpacing us. However, with the additional equipment and adjustments to spark timing, we achieved 17 seconds and over 70 miles per hour."[1]

Glenn and Keith engaged in brainstorming sessions, realizing that their engine required a more comprehensive overhaul. "Glenn began by removing the extended skirts from the pistons and incorporating Teflon buttons onto the shorter ones, thereby eliminating metal friction. We meticulously polished the connecting rods and smoothed out the crankshaft. NHRA allowed modifications to any parts, so we meticulously balanced each rod, piston, and numerous other moving components. We installed the factory-furnished camshaft, aluminum head, and the twin H-power manifold with two carburetors. Upon reassembling the engine and placing it back in the car, the transformation was astounding. Our modest 6-cylinder had been transformed into a legitimate race engine. Unfortunately, we were unable to alter the clutch or the 3-speed manual transmission, but we made adjustments to the pressure plate weights and increased the spring size, drawing inspiration from the Hornet's powertrain. This involved countless late-night hours of hard work."[1]

"We achieved a run time of 16 seconds at 82 miles per hour. This progress was heartening and marked a significant milestone in our pursuit of a racing record. We had developed our own unique trade secrets, specifically tailored to our vehicle. Our realization was that the 6-cylinder engine possessed substantial torque in the lower RPM range, reaching its peak around 3800 RPM. Consequently, we aimed to capitalize on this characteristic. This translated to an advantage at takeoff, as we had access to torque right from the start, while the V-8 engines relied on RPMs to generate more horsepower. Ongoing analysis included scrutinizing gear ratios and tire sizes to ensure compliance with NHRA's stock criteria."[1]

"We were mindful not to squander power by spinning the wheels or laying rubber due to the detrimental impact on RPM. Our ingenuity led us to discover that shifting the engine 4 inches backward, pressing it against the firewall and redistributing the weight toward the car's rear, significantly improved traction. This endeavor was monumental, requiring adjustments to the transmission linkage, clutch linkage, and numerous other components. Nonetheless, the benefits were evident, as the extra weight on the rear tires yielded impressive results. These adjustments demanded tireless effort and countless late nights."[1]

"Our little 6-cylinder powerhouse was finely tuned, displaying its remarkable capabilities. We uncovered another fascinating detail—Long Beach dragstrip's proximity to the ocean introduced moisture into the air intake. As a solution, we installed an air tester beneath the hood, ensuring an optimal air-fuel mixture. This modification proved invaluable. Crucially, our creation adhered to NHRA's strict pure stock rules."[1]

"Over time, our endeavors propelled the speed to 91 mph, with an elapsed time of slightly under 15 seconds. Our camaraderie evolved into an enthusiastic cheering section for our unique "buzz saw" Hudson Jet, resplendent with the Iron Cross emblem of "GENE'S MUFFLER" emblazoned on its doors. This circle of supporters consisted of friends rather than customers, marking an era of innocent, pure joy during the 1960s. These memories remain etched in our hearts, preserving the legacy of that bygone era."[1]

"In the grand finale, the result of our collective efforts emerged. In that year, we took the little Hudson Jet to the NHRA Winter Nationals in Pomona. Remarkably, my friend Glenn drove the car there himself. After registering, it was classified in the stock production class, the highest tier of the slowest cars. NHRA established a class winner runoff for each class one tier below ours. The class winners set their top speed and elapsed time, with the slower car receiving a head start corresponding to the time difference between the two. This unique system granted us a few seconds' advantage before the winner of the lower class could begin their pursuit. This head start proved pivotal, as our little 6-cylinder possessed formidable torque right off the line. We surged ahead by a significant margin before the competitor could even begin, choosing to keep RPMs low to capitalize on our torque advantage. The opposing class winner, perhaps due to nervousness, often ended up spinning their wheels instead of launching, providing us a substantial lead before they could recover traction."[1]

"We emerged victorious in each class, requiring us to return to the starting line to race the victor of the next lower class. With each successive run, our lead grew before their cars even started. This strategy proved effective. After five consecutive victories, we finally met our match. Glenn and I concurred: our efforts were indeed well executed. The little Hudson had exceeded all expectations and was undeniably fatigued. Nonetheless, we still secured trophies for our class and departed with immense satisfaction. The little Hudson had unquestionably fulfilled its mission."[1]

"I must remind readers that these events transpired over 60 years ago, during the early 1960s. Times have changed, and racing has evolved, but memories remain eternal. These innocent recollections are what keep the spirit of hot rods and customs alive in our modern world."[1]

Tom Kelly

In 1963 Tom Kelly designed a logo for Keith; "Tom specialized in large murals and pinstriping on motorhomes and big trucks." Tom designed a logo containing two glass packs crossing inside an Iron cross, and Keith had it made in to decals, jackets and shirts. He also painted it on the doors of some of his shop trucks.

Lake Havasu City

In 2016 Keith lived in Lake Havasu City, Arizona where he spent much of his time writing articles for some local newspapers. 78 years old he was going strong with more projects than ever. No time to retire.

Keith Christensen's Cars

Keith Christensen's 1949 Chevrolet Sedan Delivery

Keith Christensen's 1950 Oldsmobile Business Coupe

Keith Christensen's 1955 Buick

Keith Christensen's 1955 Ford Truck

Keith Christensen's 1956 Ford Truck

Keith Christensen's 1959 Chevrolet Sedan Delivery

References

Did you enjoy this article?

Kustomrama is an encyclopedia dedicated to preserve, share and protect traditional hot rod and custom car history from all over the world.

- Help us keep history alive. For as little as 2.99 USD a month you can become a monthly supporter. Click here to learn more.

- Subscribe to our free newsletter and receive regular updates and stories from Kustomrama.

- Do you know someone who would enjoy this article? Click here to forward it.

Can you help us make this article better?

Please get in touch with us at mail@kustomrama.com if you have additional information or photos to share about Keith Christensen.

This article was made possible by:

SunTec Auto Glass - Auto Glass Services on Vintage and Classic Cars

Finding a replacement windshield, back or side glass can be a difficult task when restoring your vintage or custom classic car. It doesn't have to be though now with auto glass specialist companies like www.suntecautoglass.com. They can source OEM or OEM-equivalent glass for older makes/models; which will ensure a proper fit every time. Check them out for more details!

Do you want to see your company here? Click here for more info about how you can advertise your business on Kustomrama.