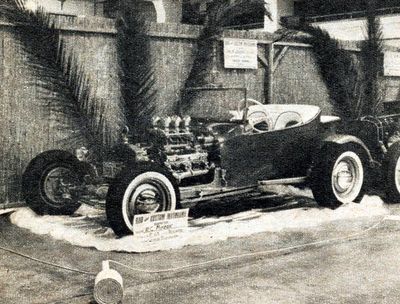

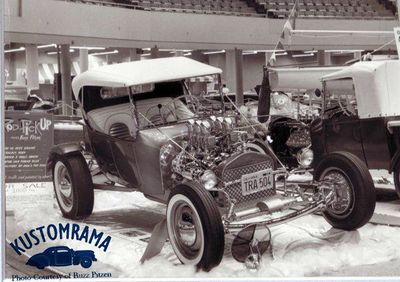

Buzz Pitzen's 1923 Ford

Fiberglas bodied 1923 Ford Model T roadster owned and built by Buzz Pitzen of Redondo Beach, California. Buzz started the build in his two car garage in 1959. He was 24 years old at the time, and he had just sold his hot rodded 1929 Ford Model A roadster to John Rasmussen. The roadster was sold so Buzz could buy his first home in Redondo Beach. Shortly after John bought the car from Buzz, he was contacted by Hot Rod Magazine, and the roadster ended up on the cover of Hot Rod Magazine March 1959. No stranger to the challenge of building a car from scratch, Buzz found out that his new two car garage was the perfect place to build his long past desire, a T-bucket.[1] Back in the 1950s it was almost impossible to find a 1923 Ford Model T roadster bucket. They were out there, but without Hemmings and the Internet, they were almost impossible to locate. According to Buzz, only the luckiest hot rodders had one, and they were not going to part with it. Buzz decided to make a body out of aluminum. After several weeks of body buck fabrication, which was a real struggle since he did not have a real body to work with, he became very frustrated, and he was not happy with the way things were going. One evening as he was reading trough an issue of Hot Rod Magazine, he came across a very, very small print for Diablo Speed Shop in Walnut Creek, California who advertised a Fiberglass T-Bucket body for sale for $149.00. The next day Buzz got them on the phone. An order was placed, payment and shipping were arranged, and Buzz's aluminum body idea was scrubbed.[2]

The body arrived as agreed. It was primed in black primer. He soon understood why, as the body was in for some serious effort to work out the imperfections. The body seam was centered at the doors, and slightly concaved. The layup was anemic, and the whole body was in need of some major fiberglass reinforcement. Buzz did not see anything he could not correct, so the work began. In fact he was so glad to have a Glass body to start with that he could not wait to get it started. As far as Buzz knows, Diablo Products only built one body before they went under, and Buzz became the lucky owner of what is believed to be the first Glass T Bucket ever made. Buzz had a clear goal with the build, he wanted to build a T-Bucket that would make the cover of the most famous car magazine in the world, Hot Rod Magazine.[2]

Buzz had a very slim budget, and when he started the project, all he had was a 1929 Ford Model A frame and the glass body. That was all he needed to start the layout of the car, and positioning components on the frame. Over the years Buzz has found this to be the most important part of any buildup. Buzz placed the body on the frame and used cardboard cut outs for the engine, rear end, radiator and axle. One of his key objectives in this phase of the build was to determine the location of the seat and foot position. On later builds, Buzz has actually used a full size cut out of himself to be sure that everything fits. He started with the fiberglass body, that needed body mounts, top bow brackets, and a dash. The body did also require major work filling as the mold seams were located down the center of the doors. Back then, all he had to work with to make those repairs was fiberglass, resin repair kits and lacquer sander filler. There were no Cal Automotive or Speedway catalogs around, so the car was pretty much handmade. The brackets were routine and went well, but the dash required a plaster mold to develop the actual fiberglass dash to house the instruments. Cardboard and mesh were used to support a plaster mold that was built on a wooden base. The dash fit agains the body, and when completed it was glassed in place. The dash was designed with the instruments set deep. The gauges were mounted on a 1/8 inch thick polished aluminum dash panel that was bolted from behind.[1]

With the body ready for placement, the frame modifications were next. The frame mods included the front cross member and spring perch, steering gear mounting bracket, all body supports, and front and rear engine mounts. With the body mounted, a rear kick up was built in the frame to set the correct height of the spring perch. A critical elevation that sat the rake of the car. Buzz was not found of too much rake on his cars. During the construction, most of the parts were made from mild steel and gas welded in place. The front spring perch was made from 1/4 inch and 1/8 inch plates. The frame was boxed in the middle. This served as the mounting position of the rear motor mount that also served as the center cross member. The rear kick ups were boxed with the same 1/8 inch plate to best match the frame material.[1]

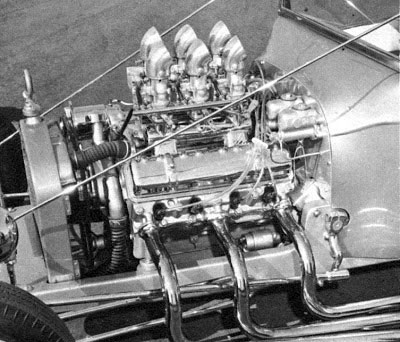

Building and positioning the steering box bracket and the front body support was critical. The steering box had to be placed at an elevation that positioned the drag link in the same arc as the radius rods. This required that the box was placed above the frame rails. It worked out well, and because of its conspicuous location got a lot of positive attention. The front body support was a 1 1/2 inch, 1/8 wall tube, bent to fit inside of the body at the cowl. Buzz used a wooden template to heat and form the bends. The support was used to hold the front of the body, the swing pedals assembly and the 1/8 inch thick polished aluminum firewall. At this stage of the project, Buzz had acquired most of the parts he needed. The engine, a 1951 Oldsmobile 334 V8, came from a wrecked Olds. it was hooked to a 1939 Ford transmission with stock gears. The front end featured a 1937 Ford tube axle. 1940 Ford hydraulic brakes were installed on all four wheels. The rear end was a 1940 Ford with 3.78 to 1 gears. All these parts were scrounged from the local junk yards and swap meets. The front radiator shell was donated by a friend. At the time Buzz promised that it would be put to good use. As it worked out, the grille shell became the only original Ford T part on the car. The radiator was built from scratch. The top and bottom tanks were found in a pile behind a very old local Radiator shop, Crandal's Radiator in Lawndale, California. Buzz went to school with Eddy Crandal, and Eddy built the radiator. He used a v cell radiator core that was ordered to size. He calculated the capacity and assured Buzz it would cool the big Olds. The grill was cut from expanded material, and the radiator was placed to allow a small cut down fan to be bolted to the water pump pulley. This combination did the job and the Olds ran nice and cool.[1]

As the build progressed, the rear end drive shaft had to be cut to length and the radius rod and springs were fitted to the frame. The front Radius rods were fabricated from 3/4 inch thick wall tubing. They were made and adapted to the tube axle using brackets welded to the axle. These had to be heli arc welded to eliminate any possible warping. The ends were made from Model A tie rod ends. The steering gear was a 1956 Ford re-circulating bearing design that Buzz found in a Main street junk yard. This box was small, easily adapted and made the steering very smooth and easy. The swing pedal was crafted from parts found in the junk yards as well. The clutch was actuated by a hydraulic slave cylinder. All hydraulic lines were cut, flared and fitted as necessary.[1]

The headlight brackets, nerf bars and windshield frame were hand formed. The windshield frame was a special challenge. Frame kits were not available then, and finding an original was not possible, so Buzz decided to make the frame from 1/16 inch steel flat 1018 material. As there were no shop that could do the u-bend needed to shape the frame, Buzz had a shop bend the material as far as the equipment could. The open U shaped frame was then pressed together to form the final u-shape. It worked out well, and the material was then cut, formed and welded to the final configuration. The rear view mirror was held in place by a nut brazed inside the frame at the top center. The side brackets were made from angle material and fit to the body. The original windshield was a one piece originally, but later Buzz modified to a folding windshield to accomodate a folding rag top. The top irons and wooden bows were all handmade. The geometry was very simple, and the goal was to make a top high enough to accomodate Buzz's height, and also fold down to rest on the rear bed. Patterns were built, and a mock up was installed. The fabrication was routine. The rear bed was simply two 14 inch metal sides bent to look like a T pick up bed. Because the parts were so short, Buzz could easily do the bending himself. The bed was boxed with upholstered plywood, and the bed inside was stuffed with a battery and a tiny gas tank.[1]

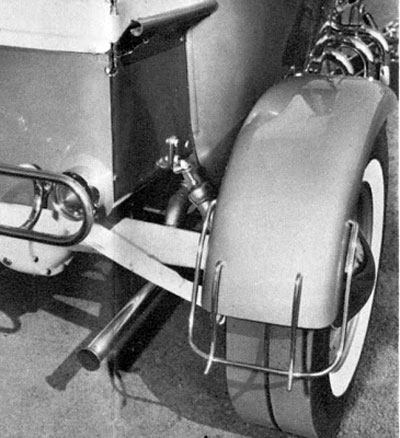

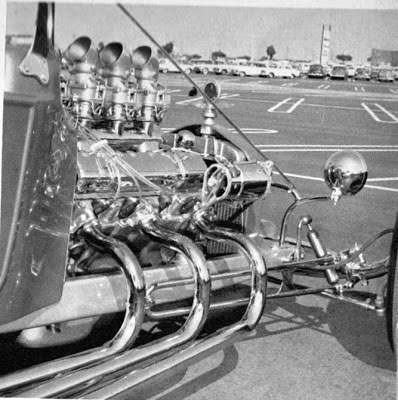

Next came the exhaust system. Buzz was inspired by a car he had seen in Hot Rod Magazine. It was to have an array of headers coming off the engine and along the body. This fabrication was a major task. The bends were all made from 1 1/2 inch exhaust pipe and bends were cut to fit as required. The gas welding went well. Buzz had taken a welding class at Inglewood High School a couple of years before. It was taught by a certified aircraft welder. The bends were welded and filed smooth for plating.[1]

According to Buzz, most speed equipment available for most V8's back in the late 1950s was Jahns pistons, Howard or Isky cams and the U-fab log Manifold. The homemade manifold was perfect for Buzz's roadster. He could use his gas welding skills and build a beautiful six jug log intake manifold to perch on top of his 334 Olds engine. He easily welded and brazed the parts together just as instructed, and the manifold worked perfectly when actuated by progressive linkage.[1]

Chrome plating was sent out as the car progressed. All plating was done by Roy of Appliance Plating on El Segundo Blvd. in Southern California. Roy had just started his business, and he gave special attention to all of the hot rodders. Roy went on to become the owner of Appliance Wheels. Buzz remembers that cost of plating was staggering, and the total for the project was around $375.00. At the time, this was about two weeks pay. But it was all worth it, as the chrome was the touch the car needed.[1]

Once assembly began, the car was prepped for paint using lacquer primer and sander filler. The paint of choice at the time was DuPont Lucite. Lacquer was still used, but was not as popular as the new Lucite. The car was shot in Buzz's garage. The fast drying Lucite made this possible and it was applied just like Lacquer. The parts were painted separately and assembled as he progressed. A final rub out was necessary to overcome his armature screw-up's, but in the end the car received a fabulous two-tone metallic blue paint job.[1]

The interior was done by Jack McNeal. Buzz considers Jack the best in the business. He was mentored by Gaylord before he started his own business on Lakewood Blvd. in Los Angeles. Jack was given these instructions: "You are the expert, the only thing I ask is when the car is finshed, it makes Hot Rod Magazine."[1]

The build took about a year, and the bucket was completed in 1960, making it the worlds first known Fiberglass T-bucket hot rod. Buzz remembers that driving the car for the first time was a little scary. The power was shocking, but the little roadster ran quiet and smooth. He never attempted to race the car though.

In December of 1960 Buzz's fiberglass dream was featured on the cover of Car Craft December 1960. According to the story, total construction cost was $1250. Two years later, in June of 1962 Buzz finally made the cover of Hot Rod Magazine with the roadster, and it entered the history books as "The Glass Image". Buzz loved the name "Glass Image", and he is not sure if it was photographer Eric Rickman or someone else on the Hot Rod Magazine staff that came up wit it. Later on, the Glass Image made the cover of the 2nd annual Hot Rod Magazine Yearbook as well. [1]

Buzz sold the roadster to the owner of Earnie's Camera Shop in Pasadena shortly after it had been featured in Hot Rod Magazine. Earnie was going to park it in the front of his shop to attract customers. Buzz have no idea what happened to the car after that.[1]

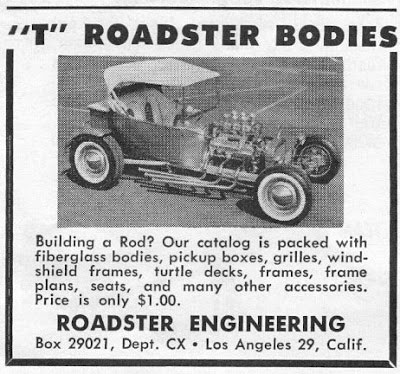

In 1964 a picture of the Glass Image was used to promote Fiberglass "T" Roadster Bodies manufactured and sold trough a company called Roadster Engineering.[2]

Magazine Features

Car Craft December 1960

Car Craft June 1961

Hot Rod Magazine June 1962

Hot Rod Magazine Yearbook #2 1962

References

Did you enjoy this article?

Kustomrama is an encyclopedia dedicated to preserve, share and protect traditional hot rod and custom car history from all over the world.

- Help us keep history alive. For as little as 2.99 USD a month you can become a monthly supporter. Click here to learn more.

- Subscribe to our free newsletter and receive regular updates and stories from Kustomrama.

- Do you know someone who would enjoy this article? Click here to forward it.

Can you help us make this article better?

Please get in touch with us at mail@kustomrama.com if you have additional information or photos to share about Buzz Pitzen's 1923 Ford.

This article was made possible by:

SunTec Auto Glass - Auto Glass Services on Vintage and Classic Cars

Finding a replacement windshield, back or side glass can be a difficult task when restoring your vintage or custom classic car. It doesn't have to be though now with auto glass specialist companies like www.suntecautoglass.com. They can source OEM or OEM-equivalent glass for older makes/models; which will ensure a proper fit every time. Check them out for more details!

Do you want to see your company here? Click here for more info about how you can advertise your business on Kustomrama.